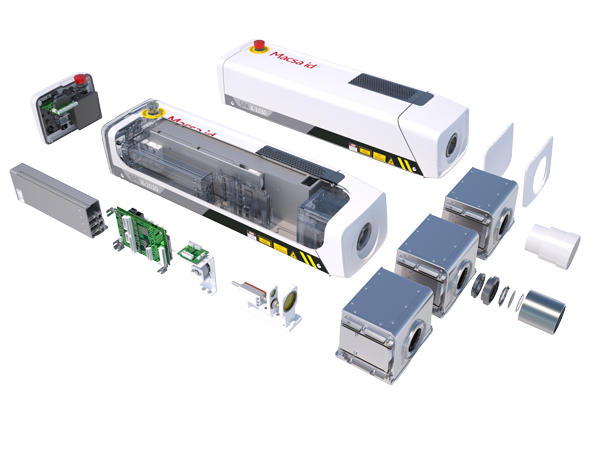

Macsa has developed the SPA Scalable Product Architecture.

The SPA laser platform simplifies everything. It’s modular so you can specify the laser which you need today knowing that you will be able to adapt it when your needs change tomorrow.

SPA lasers incorporate features and technology enabling them to deliver better quality coding and marking at higher speeds more consistently over time.

It’s not just about selling lasers but about supplying, installing and supporting complete lasers systems.

RELIABILITY

Production environments can test the reliability of laser systems. SPA lasers are designed to operate reliably in dusty or damp environments even subject to extremes of temperature.

RESISTANT TO HARSH ENVIRONMENTS

They have been designed to meet IP54. This means that they are dust

tight. This makes them more reliable.

Furthermore an affordable IP65 option is avaliable. This enables them to be equally reliable in wash down and other wet environments.

High and low temperature kits are avaliable so that users can be

confident that performance will be mantained even at ambient temperatures outside the laser’s normal operating range.

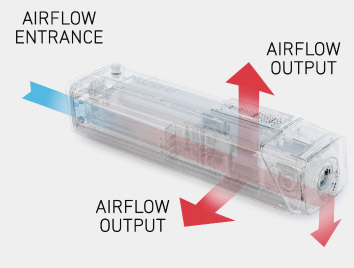

CLEAN COOLING

The SPA laser uses the novel RAF reverse airflow cooling system. It takes in air from the back of the laser where it does not pick up dust from the laser’s operation. This means that filters are changed less frequently and in some circumstances are not needed.

There is a sealed air system which transfers heat form the laser to the cooling air itself. This means that there is no risk of any dust being deposited directly into system component.

Finally, a part of the exhaust air is blown over the focusing lens keeping it dust free so that print quality is maintained without the need for operator intervention.

![]()

RELIABLE CONNECTIVITY

The connectors on the back of SPA lasers are high specification and reliable in harsh production environments. They ensure that communication is maintained without the risk of disconnection or data transfer errors.

![]()

VERSATILITY

The modular system on which the Macsa SPA is based enables the laser to easily adapt to the needs of every production line or marking type. The SPA is so versatile that a single unit can meet the requirements of many applications.

EASY LENS INSTALLATION

The Macsa SPA lets you exchange lenses safely and quickly, which means that you can select the set of lenses that is suitable for each project and easily adapt the laser to it.

OPTICS KITS FOR IMPROVED CODING

The Macsa SPA gives you the option of adding an Optics Kit that includes elements to improve the focus and resolution of the coding, such as a laser beam expander or an optical pointer, among others.

EASY SWITCHING BETWEEN HEADS

Thanks to the SPA printer head exchange system, operators can switch them on site with just two connectors, adapting the laser to the needs of the production line at all times.

![]()

A LASER FOR EVERY SUBSTRATE

SPA works with CO2, YAG and Fiber laser technology to provide the best coding and marking result on a wide range of materials.

3D PRINTING OPTIONS

The SPA enables you to print on multi-level surfaces thanks to a surface recognition system included in its 3D printing kit, which ensures an optimal focal point at all times.

EXTERNAL Z-AXIS CONTROL

Macsa provides you with an external Z-axis controller that allows you to adapt the SPA’s vertical coding axis in order to vary the height between print cycles and adapt it to different products.

CONNECTOR BOX

The SPA connector box offers a wide range of communication ports, which ensure that the laser is integrated with all of the elements in your production line.

CONNECTIVITY

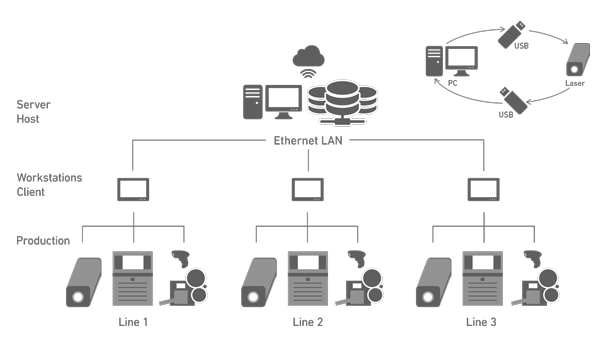

The SPA laser platform can work individually, but it can also work in team. These are the connectivity options:

iLABEL SYSTEMS

Just press a button, that’s all. The SPA system will print the label and apply it wherever you want. The wide range of possibilities of iLABEL systems guarantees the use of all kinds of labels for any

type of application.

REMOTE CONTROL

A Macsa’s technician will be able to set the device and help in the creation of messages remotely.

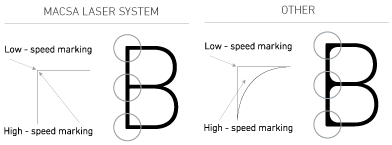

PRECISION

Quality marking speaks volumes to the consumers of a brand or product. That is why the SPA platform has been designed to offer maximum marking resolution and definition, even on high-speed production lines.

HIGHER SPEED AND BETTER RESOLUTION

There are three basic SPA printheads to use for different speed/quality challenges:

- The UHS printhead is recommended for very high-speed production lines and for multiple lines of code or for complex messages with graphics and 2D codes.

- The HPD printhead is recommended for working on difficult substrates, large marking areas and high resolution graphics and for product modification.

- The NXT is a utility printhead for applications requiring a balance of power and speed.

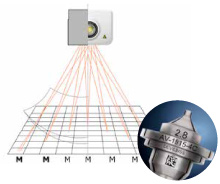

HIGHER -QUALITY LENSES

SPA lasers operate with new high-definition flat field lenses. These enable higher quality coding on a wide range of materials and across the entire marking area.

DUAL PROCESSOR

SPA has a dual processor that dedicates all the resources of one processor to operating the laser, and simultaneously dedicates the resources of the other processor to real-time control of the marking, thus increasing the precision of the coding.

VIBRATION CORRECTION SYSTEM (VCS)

Macsa’s propietrary VCS, based on a novel approach to product detection, improves print quality by eliminating the impact of production line vibration.

![]()

LASER BEAM EXPANDER

A beam expander is avaliable as an SPA option. This expands the beam making it more uniform and increasing the definition of coding.

OPTIMUM FOCUS CONTROL

Obtaining the optimum focus distance is much easier with the SPA as it includes a light pointer for the laser beam that indicates the height at which to place the product for better print definition.

ADAPTABILITY

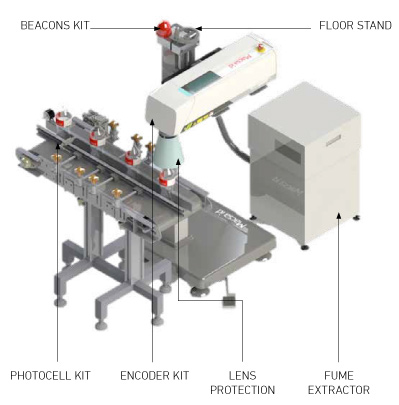

ESSENTIAL EXTRAS

A laser doesn’t deliver until it’s installed and running, this is the reason why it needs essential accessories. Macsa makes these essentials avaliable as a part of the SPA package. They are chosen because they work well within a SPA system and Macsa is confident to recommend them.

- Product detectors

- Line protection integration

- New articulated floor stands

- Special application cabinets (Workstations)

- Cooling dryer

- Fume extractors

- Lens / operator protection

- Safety kits

OPTIONAL EXTRAS

Every production environment is different. Different performance, different ambient conditions, different regulations, different products and different substrates. Macsa supports and makes available a range of extras which meet the standards and complement an SPA laser installation.

- Optic kits

- Environmental kits

- Warming kit

- Cooling kit

- Connector box

- Filters

- Chiller

- Mechanical head kits

SIMPLICITY

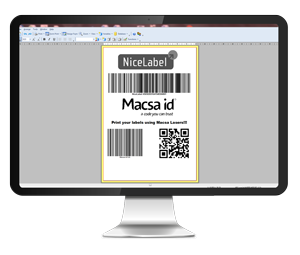

Macsa has used the SPA software environment to make it easy to install, program and operate SPA lasers. There’s a wizard to support installation. There are on-line help videos to provide advice in situ.

There is a completely new user interface to make programming quicker and to eliminate operator errors.

MULTIMEDIA GUIDE FOR INSTALLATION AND CONFIGURATION

SPA lasers are even easier to install and configure thanks to the technical guides, videos and tips that can be accessed on site via a touch screen.

ALL OPTIONS AT YOUR FINGERTIPS

SPA lasers may be controlled by a best of class 10 inch handheld touch screen controller. It comes complete with a new version of Marca software which is even easier to use and more powerful than previous releases. SPA lasers may alternatively be controlled direct from a PC via an ethernet link.

RESPONSIBILITY

At MACSA ID, this is what we do. We are a team, or better yet, a family. From the moment of our inception, our family has grown exponentially to meet the challenges of tomorrow, today. We strive to offer the best solutions in laser marking and coding for product traceability. And in so doing, eliminating the need for costly consumables and at the same time protecting the environment. The results of the applicability and versatility of our products can be found in the daily lives of people around the world.

In the end, that’s what we ‘re all about : people helping people.

MACSA HAS A RESPONSIBLE APPROACH TO THE ENVIRONMENT AND A CLEAR AND VISIBLE ETHICAL POLICY

MACSA, THANKS TO ITS WIDE OFFER OF CODING AND MARKING EQUIPMENTS OF ALL TECHNOLOGIES, HELPS TO FULL FILL ALL SECTOR REGULATIONS

Macsa also understands the regulations wich apply to our customers’ business and takes them into account in its product development.

* 21CFR/11

* GSD Data Matrix

* DCTA Tobacco